Managing Rising Equipment Costs for Farm Profitability

The last few years have seen an environment of inflation and rapidly escalating costs for new equipment and repairs. These rising costs significantly impact grain farms, where equipment expenses are often the largest overhead cost. Given the crucial role of equipment in farming operations, understanding whether your costs are at, above or below-average is essential for maintaining a competitive edge. However, access to competitor information can be challenging, making this task difficult.

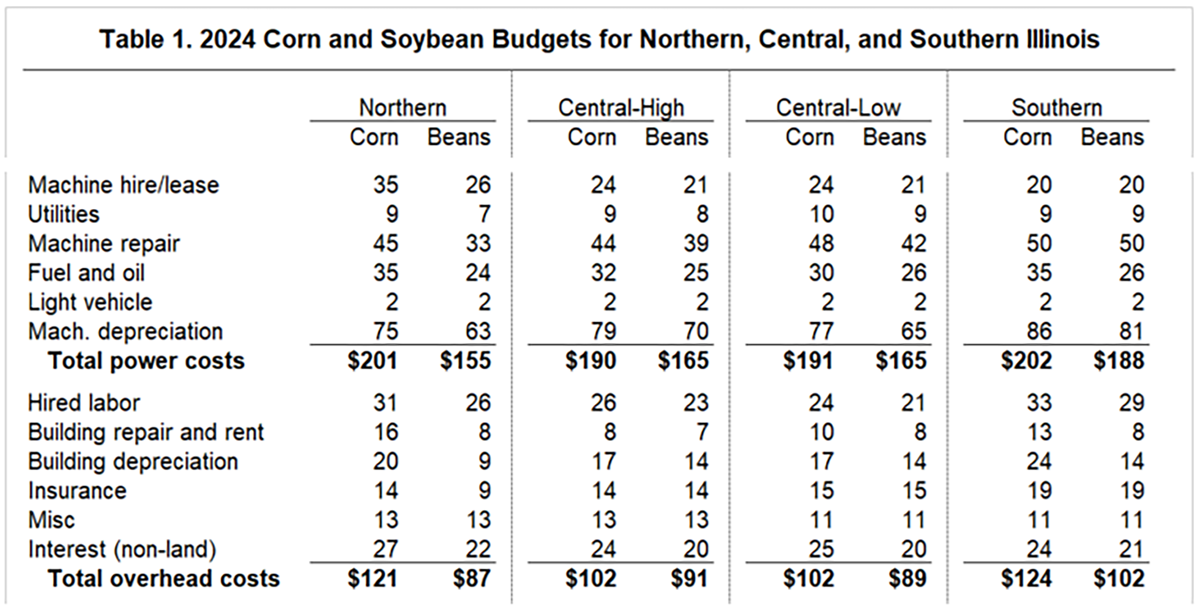

Fortunately, there are a couple of options for benchmark comparisons regarding overhead and machinery costs. One valuable resource is the University of Illinois farmdoc, which provides projected budgets based on farmer data in the Illinois Farm Business Financial Management system. This data allows farmers to compare their expenses against industry standards.

Comparing this data to 2020, there has been a noticeable increase in costs. Power costs, for instance, are up approximately $65 per acre for corn and $20 per acre for soybeans. Overhead costs have also risen, with an increase of about $25 per acre for corn and $15 per acre for soybeans. These figures support the sentiments of many farmers who feel their production costs continue to rise. This trend underscores the importance of maintaining a competitive cost structure for grain farm profitability, especially given the high costs of modern equipment and repairs.

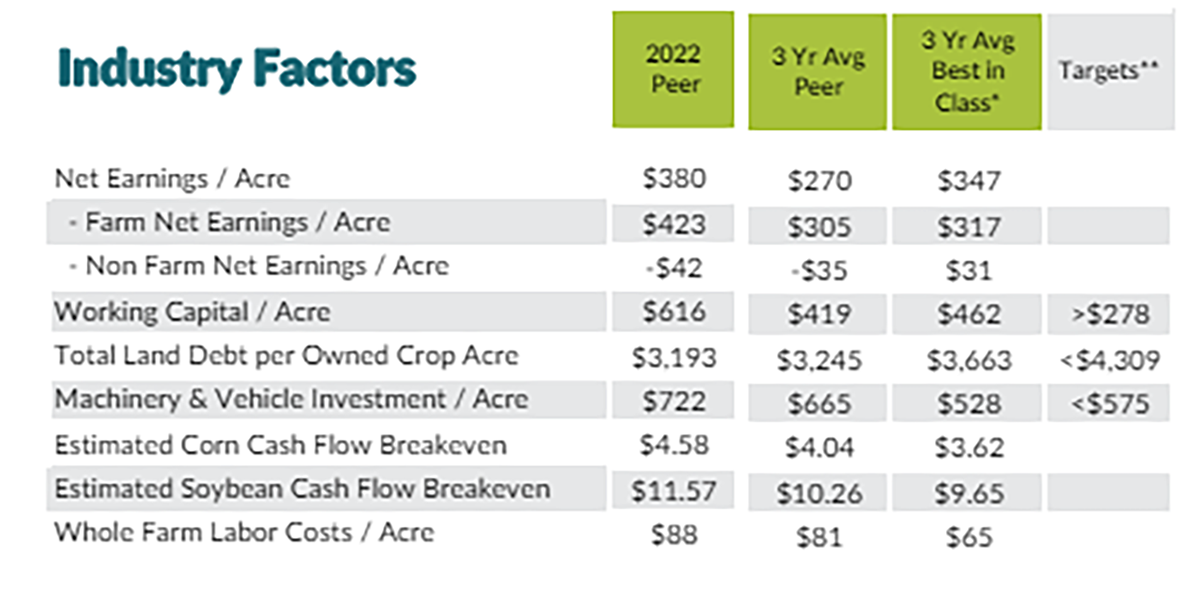

At Compeer, we understand the challenges farmers face in managing farm equipment costs. We maintain industry benchmark information for the industries we finance, providing valuable insights for our clients. While our data may not be as detailed as that from University of Illinois, we do track machinery investment per acre. This metric has shown a steady increase in recent years, reflecting the overall rise in equipment costs.

The importance of farm benchmarking cannot be overstated. By comparing your expenses to industry standards, you can identify areas where you may be overspending and take steps to improve efficiency. This process involves not just looking at the costs of purchasing new equipment but also considering the long-term expenses of maintenance and repairs.

Examine Your Existing Fleet

One practical step in managing equipment costs is to conduct a thorough analysis of your current machinery. This includes addressing the age, condition and efficiency of your equipment. Older machines, while fully depreciated, may have higher maintenance costs and lower efficiency compared to newer models. In contrast, newer equipment, though more expensive upfront, can offer better performance and lower operating costs.

Research Alternative Sourcing Options

Another strategy is to explore options for equipment leasing or rental. These alternatives can provide access to the latest technology without the high initial investment. Leasing can offer tax benefits and improve cash flow management. Additionally, participating in machinery-sharing programs with neighboring farms can be a cost-effective way to maximize equipment usage and reduce individual expenses.

Equipment costs represent one of the most significant challenges for grain farmers today. However, by leveraging farm benchmark data, conducting thorough machinery analyses and exploring alternative acquisition methods, farmers can better manage these expenses. Maintaining a competitive cost structure is key to long-term profitability, and effort spent analyzing and optimizing your operation will be time well spent.

|

-270x321-31df7c8.png?)